Yuken Unloading Relief Valves

These valves are used to operate pumps at the minimum load in an accumulator circuit or in a high-low pump circuit. In an accumulator circuit, when the system pressure reaches a preset level (i.e. cut-out pressure), the valve opens to divert the pump delivery to the reservoir at low pressure; thus, the pump is unloaded automatically. When the system pressure drops to the cut-in pressure (approximately 85% of the cut-out pressure normally), the valve closes to direct the loaded pump delivery to the accumulator and the hydraulic system.

Yuken Counterbalance Valves

These valves maintain hydraulic pressure in a hydraulic system or load backpressure on a cylinder. If the inlet pressure exceeds a preset level, flow is released to keep the pressure constant. They are accompanied with a check valve that allows the flow for lifting a cylinder up to freely pass. To control the cylinder speed, those with meter-in control (see P. 33) are generally used for both upward and downward movement of the cylinder. Similar to the sequence valves, some counterbalance valves are equipped with an auxiliary pilot port.

Yuken Sequence Valves

These valves control the sequential operation of two or more actuators. If the inlet pressure exceeds a preset level, they deliver effective pressure to the outlet side. The valves can serve as pressure holding valves to maintain hydraulic pressure in a circuit. When a sequence valve is installed between a directional control valve and a cylinder, it needs reversed free flow; therefore, the valve should contain a check valve. The sequence valves and counterbalance valves, described in the next section, are generally known as H/HC type pressure control valves, and how they are assembled determines the nature of the combined valve, either H or HC type.

Note that a sequence valve with an auxiliary pilot port can provide two-pressure control (high/low) by delivering the pilot pressure of the auxiliary pilot port to the pilot piston. Pressure required for this auxiliary remote control is approximately 1/8 of the adjustment pressure (approximately 1/16 when the adjustment pressure is 7 MPa (1 015 psi) or more). The example is shown in Fig. 3.10.

Yuken Solenoid Controlled Relief Valves

These valves are a combination of a pilot operated relief valve and a small solenoid operated directional valve. Sending electrical signals to the directional valve can remotely unload pump pressure or conduct the two- or three-pressure control in hydraulic circuits. For adjusting pressure in the two- or three-pressure control, use one or two direct type relief valves.

Yuken Pilot Operated Relief Valves

These valves consist of a balanced piston for bypassing excess flow in hydraulic circuits and a pilot that controls the piston motion and pressure. Placed in a vent circuit, they can perform remote control, unloading, or two-

pressure control.

Specifications of the pilot operated relief valves (Fig. 3.3) are shown in Table 3.1. In addition, low noise and high pressure types (35 MPa (5 076 psi) Max.) are also available.

Figure 3.4 shows characteristics of flow vs. pressure (pressure override) of the relief valve, 3/4-size. Figure 3.5 shows characteristics of flow vs. vent pressure and the minimum adjustment pressure. A vent pressure is a relief pressure released upon opening a vent.

When the flow exceeds a certain level, the vent pressure rapidly increases with flow resistance. The minimum adjustment pressure refers to a relief pressure obtained when the control pressure of the pilot valve is set to the lowest level.

When a relief valve is loaded with a circuit as depicted in Fig. 3.6, the transient pressure characteristics appear as shown in Fig. 3.7. t represents a delay time of the relief valve and T, that of the system. The smaller the pipe capacity and the lower the pipe pressure, the shorter the delays t and T. To evaluate the delays of the entire system, both t and T must be taken into account.

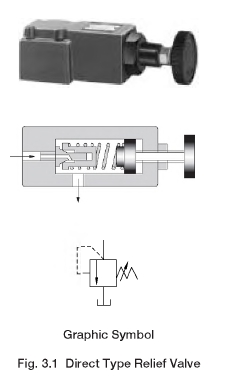

Yuken Direct Type Relief Valves

These valves are small and have a simple structure for their capacity. However, they are likely to exhibit high- pressure override (a pressure characteristic observed when a fluid starts flowing from a valve and reaches the rated flow rate) and chattering. Therefore, they are used to control the pressure of relatively small flows, as shown in Fig. 3.2. Valves of the size 1/8, in particular, are very popular for pilot pressure controls.

Yuken Reciprocal Pumps

These pumps have pistons installed at right angles against the pump rotating shaft in a plane including the shaft. The pistons reciprocate with alternately moving cranks or eccentric cams. Pumps suffer from discharge pulsation because they have a fewer pistons than the axial and radial types; however, they can operate at a high pressure of up to 100 MPa (14 504 psi). These pumps are used for high-pressure applications such as construction vehicles, cargo-loading machines, and press machines. In addition, they can handle water or water-containing fluids as the working fluid because of the construction to be wider area applicable for lubrication.

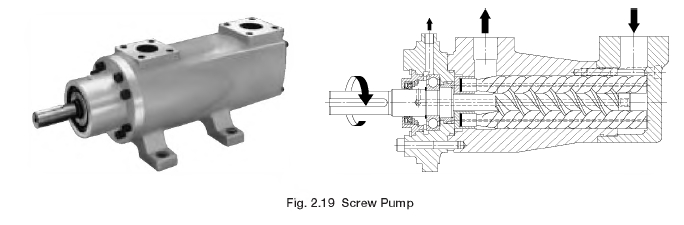

Yuken Screw Pumps

These pumps operate by rotating two or three screw shafts, which are aligned and engaged in parallel, to continuously convey a volume structured with screw leads. Unlike the other types of pumps, they have no intermittent displacement variation and abrupt pressure variation. Because of the low noise level and reduced pulsation, they are used as hydraulic pressure sources for hydraulic lifts and submarines. Because gear pumps are less susceptible to working fluid contamination, they are also used for pumping cutting oils and lubricants.

Figure 2.19 shows an example of the triple-screw type, which can operate with up to 25 MPa (3 626 psi) at 3 600 r/min or less. The pumps are available in displacements of 700 L/min (185 U.S.GPM) or less for high pressure operation and 1 800 L/min (476 U.S.GPM) or less for low pressure operation.

Yuken Gear Pumps

These pumps operate with two gears engaged with each other and rotating to feed a hydraulic fluid from the suction area to the discharge area. They all have fixed (constant) displacement capacities. They are categorized into external and internal gear pumps; the internal type generally has smaller discharge pulsation and lower noise level than the other. The gear pumps are relatively resistant to working fluid contamination. Pumps operate at 20 to 25 MPa (2 901 to 3 626 psi) and offer a displacement of 100 cm3/rev (6.10 cu.in./rev) for the single type. Similar to vane pumps, double type gear pumps are easy to construct.

High pressure gear pumps often adopt involute gears, which allow highly accurate processing, bringing about high system operation efficiency. Contacting with each other at two points, the gears rotate to entrap oil in the engaging parts, resulting in vibration and noise, which are reduced by a groove on the side plate allowing the oil to escape. Some low pressure gear pumps use trochoid gears. Figures 2.17 and 2.18 show the external and internal gear pumps.

The displacement of external gear pumps is determined by a chamber between the neighboring gear teeth and the inner surface of the casing; the displacement of the internal gear pump is determined by a chamber between the external and internal gears and a dash board. The crescent-shaped dash board (filler piece) separates the suction and discharge areas. For both the types, the sides of the gear teeth are sealed with side plates. The high pressure external gear pumps have a movable side plate by which high pressure flow is led to the rear side to press against the gear and keep a suitable clearance.

Gear pumps consist of relatively simple parts. They offer high suction performance at a low cost and are used in various fields: forklifts, industrial platform vehicles, construction machines such as excavators and wheel loaders, and supporting pumps for primary pumps. Compact packages containing the gear pump, safety and check valves, oil reservoir, and DC motor are popular in automobiles.

Yuken Variable Displacement Vane Pumps

Vane pumps can be transformed to the unbalanced type by making the center of the round cam ring eccentric to the rotating shaft; this type provides a pair of suction and discharge processes. The pumps can also be transformed to the variable displacement type by making the cam ring at the maximum eccentricity concentric with the shaft (the output flow continuously reduces to zero). The variable displacement type is not pressure balanced and has a greater force in the radial direction than the fixed displacement type.

Figure 2.16 shows the appearance and cross sectional view of a typical small-sized variable displacement vane pump. It is a pressure compensator type with a mechanism that uses a spring to make the cam ring eccentric to the maximum level at a low pressure. However, when the pressure reaches a preset level, the hydraulic power exceeds the spring force to reduce the eccentricity.

The variable displacement vane pumps that offer displacements of 8 to 22 cm3/rev (.488 to 1.34 cu.in./rev) and operate at 7 MPa (1 015 psi) or less are widely used in small machine tools because of inexpensiveness and low noise level. Those that offer a displacement of 160 cm3/rev (9.76 cu.in./rev) and operate at 16 MPa (2 321 psi) or less are also available.

Similar to the piston pumps, large-volume variable displacement pumps with load sensing control are commercially supplied; however, the variable displacement pumps are generally used in low/middle pressure ranges.