Decompression Circuit

Releasing compressed working fluid instantly back to a reservoir generates shock waves. Compressed working fluid must be released gradually. In Fig. 15.7, compressed working fluid in the cylinder cap is released gradually through the flow control valve. This reduces circuit pressure slowly, thus preventing shock waves.

After completion of pressure release, this circuit achieves automatic lift of the cylinder by electric signals from the pressure switch.

After compressing working fluid in the cylinder cap, the solenoid of the decompression valve is turned ON. Then, the compressed working fluid is released back to the reservoir through the flow control valve. Pressure in the circuit drops until it hits a certain point set in the switch PS. Then, the switch transmits signals out, and turns the solenoid valve ON to lift the cylinder. By this sequence, a smooth lift-up-and-down motion is achieved.

Two-Pressure Circuit with Decompression and Check Valves

In the cylinder-forwarding process (solenoid OFF), circuit pressure is kept at 10 MPa (1 450 psi). But, in the cylinder returning process (solenoid ON), circuit pressure is controlled at 7 MPa (1 015 psi) by the decompression valve.

Circuit with Two-Pressure Two-Control Type

When pump pressure is lower than PL, the angle of the swash plate becomes maximum, and the output flow reaches to the maximum (the flow rate goes to QH). In contrast, a pump pressure higher than PL causes a smaller swash plate angle and smaller output flow (QL). When the circuit pressure equals pump pressure, the swash plate angle falls close to zero, and output flow reduces to the amount of internal leakage. In this circuit, the power of the electric motor is kept small.

Circuit with Accumulator

Pressure switch PS is correlated with the solenoid valve; when the circuit pressure equals the pressure set in the pressure switch PS, the solenoid valve is turned off, and output flow is by-passed to the reservoir, but the accumulator keeps the circuit pressure constant.

Pump-Relief Unload Circuit

The circuit shown in Fig. 15.3 contains ® a low pressure and large volume pump and © a high pressure and small volume pump. The circuit raises its efficiency by using ® and ©. In a case where the pressure in the circuit is lower than the pressure set at the unload valve, the output flow rate from ® and © are gathered and provided to the circuit. In contrast, in a case where pressure in the circuit is higher than the pressure set at the unload valve, the output flow rate from ® is by-passed to the reservoir by the unload valve, and the pressure is unloaded. In this case, pressure within the circuit is kept at a certain level by the output flow rate from © only. This circuit provides flow rate characteristics observed in a pressure vs. flow rate curve.

Circuit by Pressure Compensated Pump

This circuit reduces the amount of output flow rate by using the variable displacement pump with pressure compensating function. The pressure of the system is raised to a set level even when it is in idle.

Open Center Circuit

Figure 15.1 (a) shows a circuit in which output flow from the pump is by-passed to the reservoir with the spool of the PT connection valve at the center position. In the case of solenoid pilot operated directional valves, as shown in Fig. 15.1 (b), the check valve is required to maintain the minimum pilot pressure of the valve.

Unload Circuits

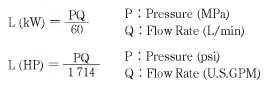

These circuits enhance the product life and efficiency, at the same time, keeping the power consumption and heat generation at a low level when the system is in waiting mode. Hydraulic power is expressed in the following equation.

As shown, hydraulic power is proportional to the product of pressure and flow rate. Reducing either exponent then leads to lessened hydraulic power.

Biodegradable Fluid

Biodegradable working fluid is decomposed by microbes to CO2 and H2O, and, therefore, does not have a negative impact on the environment. Base oil is primarily polyethylene glycol or vegetable oil (rape seed oil). The demand for biodegradable working fluid is particularly high for equipment used outdoors, such as excavators and tunnel linings. Table 14.9 sums up the drawbacks of and treatments for biodegradable working fluid in piston pumps. Attention needs to be paid to mineral oil left inside the system; mineral oil and biodegradable oil should not be mingled. In systems in which attachments are used, residual oil left in attachments requires especial caution.

Fire Resistant Fluid

Whenever fire is present around hydraulic equipment, it cannot be over stated that operators and personnel working in the vicinity are always in danger from potential fire disasters. Working fluid compressed within the equipment can possibly burst out through fractures, cracks, and pinholes. It is almost impossible to stop leakage from the equipment, if it includes exudation and dribbling. The danger of fire disaster can thus never be neglected.

Detailed records of fire accidents have not been kept since hydraulic equipment has become widely utilized. But, actual accidents have occurred quite frequently. The large number of specifications made to assess the flammability of fluids testifies to this fact.

Working fluids chosen for their fire resistance capability are grouped and shown in Fig. 14.8. Many specifications have been created to assess flammability from multiple points of view. One specification compares the flammability of petroleum and hydraulic working fluid, and another compares the relative flammability of two different fire-resistant working fluids. Proper selection should be made based upon applications and conditions, etc.

Possible reasons for fire disaster are presented below. The specifications of combustion tests give due consideration to these causes.

(1) Working fluid is misted out, and ignited.

(2) Working fluid is directly poured into a source of fire.

(3) Working fluid exuded from equipment, or left on rugs or materials, is ignited.

Flammability test methods are categorized into the following two major groups.

(1) The test gradually increases temperature to the point of ignition, or increases the chance of ignition in a test object. From this, a quantitative scale can be extrapolated. Flash point tests, spontaneous combustion tests, and pipe cleaner tests are representative of this type of test.

(2) The test is a qualitative method that requires that the conditions necessary for ignition take place. Fluid is left in those conditions and observed to see whether ignition takes place or not. High pressure gas exhaust tests and manifold ignition tests are representative of this type of test.