Deceleration Valves/Deceleration and Check Valves

These valves continuously regulate flow rates, using a cam mechanism. Pushing the spool down decreases the flow rate for the normal open type and increases it for the normal close type. When the normal open type is installed to cushion the cylinder piston, accurate stroke end control is difficult. In this case, the restrictor and directional control valve should be adjusted so that the piston slowly returns to an intended position and then stops.

Flow Control Valves/Flow Control and Check Valves

These valves consist of a pressure compensator (pressure reducing valve that keeps the pressure difference constant) and a restrictor. They maintain a constant flow rate, independent of the inlet-outlet differential pressure. Provided with a sharp-edge orifice, they can also work regardless of fluid temperature or viscosity.

In a circuit where the flow rate is regulated to a low level, the control flow may be momentarily exceeded, leading to jumping of the actuator. This phenomenon is related to a time lag until the pressure compensating piston is properly positioned for flow control. To prevent the phenomenon, the piston stroke should be adjusted according to the inlet- outlet differential pressure.

Flow control valves are basically used as follows.

(1) Meter-In Control

The control valve is connected in series with the cylinder inlet to directly control the input flow. Prior to the control valve, a relief valve is applied to excess flow, which escapes through a relief valve. In a circuit where load is applied in the direction of piston travel, the control valve may lose cylinder speed control.

(2) Meter-Out Control

The control valve is connected in series with the cylinder outlet to directly control the output flow. Prior to the control valve, excess flow escapes through a relief valve to a tank. This circuit design is used for applications where the piston could move down faster than a control speed, as in the case of vertical drilling machines, or where there should always be a back pressure in the cylinder. Careful attention should be paid to the fact that the cylinder outlet pressure may rise above the relief pressure produced in the circuit.

(3) Bleed-Off Control

The control valve is installed on a by-pass line to regulate flow to the tank and control the actuator speed. Compared to the other control circuits, this circuit works with small power consumption because the pump’s discharge pressure is fully delivered to the load resistance. Given that the bleed flow is constant, the fluctuation of pump flow determines the actuator speed. In other words, the pump discharge flow directly influences the load and the pump’svolumetric efficiency.

This circuit does not allow for control of multiple actuators.

Figure 5.4 shows flow control circuits provided with the control types (1) to (3). PG* indicates the pressure at each point observed when the cylinder is operated at the load pressure of 4 MPa (580 psi). The mechanisms of the meter-in and -out control can be understood by comparing the positions and inlet/outlet pressures of the flow control valves and the inlet/outlet pressures of the cylinders in the meter-in and -out control circuits. The higher cylinder outlet pressure in the meter-out control circuit suggests that the cylinder area difference results in pressure intensification. Also, differences between the bleed-off control and the other control types are clear in the relief valve pressures and the cylinder inlet pressures. The pressure values in the figure are based on the assumption that there are no pipe resistance and pressure loss through the valves.

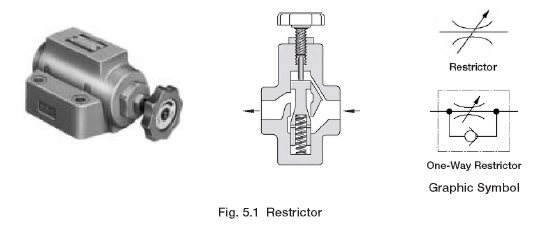

Yuken Restrictors/One Way Restrictors

These valves regulate flow rates in hydraulic circuits. They have the advantages of plain structure, simple operation, and wide range of adjustment. On the other hand, they cannot accurately control the flow; even through the fixed restriction, the flow varies with the inlet-outlet differential pressure and the fluid viscosity. Therefore, these valves are placed where the pressure difference varies little, and high control accuracy is not required. The one-way restrictors regulate flow in one way, while allowing reversed flow to freely pass through.

History of Solenoid Operated Directional Valve, Size 1/8

The solenoid operated directional valve in 1/8 size (DSG-01) was first named Design 10 and authorized as a complete engineering release in 1966. Until the release of Design 70 in 2004, its major specifications were updated over 38 years, as shown below. Now, the Design 70 is capable of handling five times the pressure and 16 times the flow rate of the original Design 10; however, the valve mass remains approximately 1.2 times.

Note that the former pressure unit, kgf/cm2, is used here for convenience. The conversion to the SI unit is as follows: 1 kgf/cm2 = 0.1 MPa

Yuken Multiple Control Valves

These valves have multiple functions, including direction, relief, and check control in one body and are mainly used for vehicles. Whether the functions are to be activated individually or simultaneously determines the circuit type: parallel, tandem, or series. When the directional control function is not working, the pump output flow goes through the valve into the tank. For this reason, power loss and heat generation are minimum. The mono block construction, which houses multiple spools in one body, and the sectional construction, which is modular by valve function, are available. For directional control, manual, solenoid, and proportional control valves are offered.

Yuken Pilot Operated Check Valves

These check valves have a pilot piston, which works with remote pressure to open the closed check valve, allowing reversed flow. Two types, standard and decompression, are available. The decompression type has a main poppet valve combined with a decompression valve. When the pilot pressure increases to lift the pilot piston, the decompression poppet valve opens first, and then the main poppet after the pressure is reduced. These valves are used to moderate shock caused by a sudden pressure release, which often occurs during the return stroke of a press process. They maintain the actuator position and system pressure, opening/closing the seat; therefore, internal leakage can be kept at minimum.

When they are used with a restrictor or a counterbalance valve that produces back pressure on the outlet side of reversed free flow, a counter force may work on the piston, which opens/closes the poppet continuously and vibrates the valves as a result. If the valves are in such a hydraulic circuit, the external drain type should be used. Figure 4.13 shows the pilot operated check valve (CP*G- 06). Figure 4.14 shows the relationship between the minimum pilot pressures and the pressure at the inlet side of reversed free flow. Figure 4.15 shows the pressure drop characteristics in the free flow and in the reversed flow.

Figure 4.16 shows circuit examples of the internal and external drain types. When the outlet side P1 is directly connected to the tank in reversed free flow (a), the internal drain type is normally used. When back pressure is applied to the outlet side P1 (b), the external drain type should be used.

Yuken Check Valves

These valves allow free flow in one direction, while preventing flow in the reverse direction. They are used to prevent reversed flow, and two check valve types, in-line and right angle, are available. The poppet opens when the inlet pressure exceeds the spring force. The pressure at which the poppet starts to open is called cracking pressure. Check valves are often incorporated in sequence valves or pressure reducing valves to let them open in one direction and bypass the free flow in the reverse direction.

Figures 4.10 and 4.11 show the in-line and right angle check valves, respectively. Figure 4.12 shows their pressure drop characteristics.

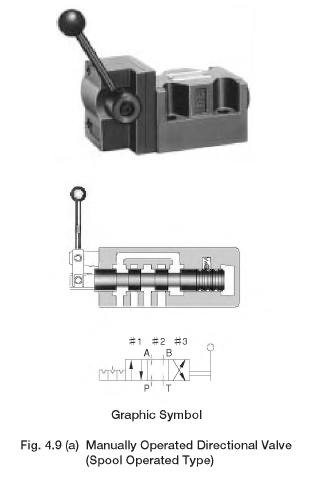

Yuken Manually Operated Directional Valves

These valves are manually operated to change the direction of hydraulic flow. They are available in the spool-operated and rotary types. These valves are structured in two types, detent and spring. The detent type maintains the spool position at the time the lever is operated, and the spool is returned to the center by the spring force. The spring type springs back the spool to either position of changeover, as is in the two-position valve. Figure 4.9 shows the spool-operated type and rotary type directional valves, respectively.

Yuken Pilot Operated Directional Valves

These valves perform spool changeover by the hydraulic pilot. They are useful when the pilot directional control valve and the main directional control valve should be installed distant to each other. The pilot pressure for spool operation is 0.5 MPa (72.5 psi) at minimum. Figure 4.8 shows the pilot operated directional valve (DHG-06).

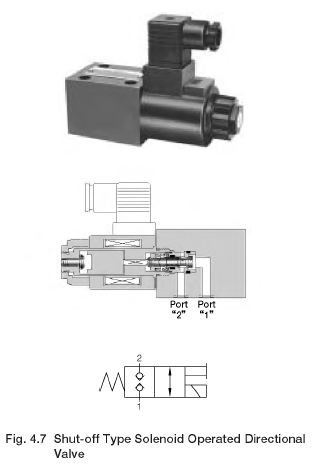

Yuken Shut-off Type Solenoid Operated Directional Valves (Poppet Type Two-Way Solenoid Operated Directional Valves)

These valves are solenoid-operated two-way directional valves that operate a poppet valve by the solenoid to open/ close hydraulic passages. Two types of them are available: cartridge and sub-plate mounting. Because they are the poppet type, the internal leakage is almost zero. Figure 4.7 shows the shut-off type solenoid operated directional valve (DSPG-01).