Proportional Electro-Hydraulic Flow Control and Relief Valves

These valves facilitate energy-saving operation of hydraulic systems by supplying the minimum pressure and flow required to drive the actuators. These valves control the pump pressure effectively by responding to a small pressure difference against the load pressure. They could be described as energy-saving meter-in type flow control valves that can be operated at low power consumption. Also, they are provided with a linear variable differential transformer for detecting the throttle position, allowing reliable and high-accuracy control.

Proportional Electro-Hydraulic Flow Control (and Check) Valves

These valves are flow control valves provided with a proportional DC solenoid on the restrictor. They can smoothly start, stop, and accelerate/decelerate the actuator through a controlled input current.

Proportional Electro-Hydraulic Relieving and Reducing Valves

These valves consist of a proportional electro-hydraulic pilot relief valve and a pressure reducing and relieving valve. They can control the system pressure continuously through a controlled input current to the DC solenoid. Because the valves have a relieving mechanism, a good response speed in reducing the pressure even at a large load capacity can be obtained.

Proportional Electro-Hydraulic Relief Valves

These valves consist of a proportional electro-hydraulic pilot relief valve and a low noise type pilot operated relief valve. They can control the system pressure proportionally through a controlled input current.

Proportional Electro-Hydraulic Pilot Relief Valves

These valves consist of a proportional DC solenoid and a direct type relief valve. Connected to the vent port of a relief valve or a pressure reducing valve, they can continuously control the pressure through a controlled input current to the DC solenoid.

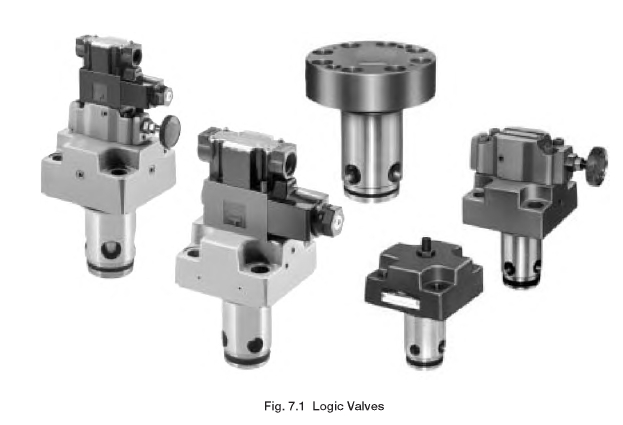

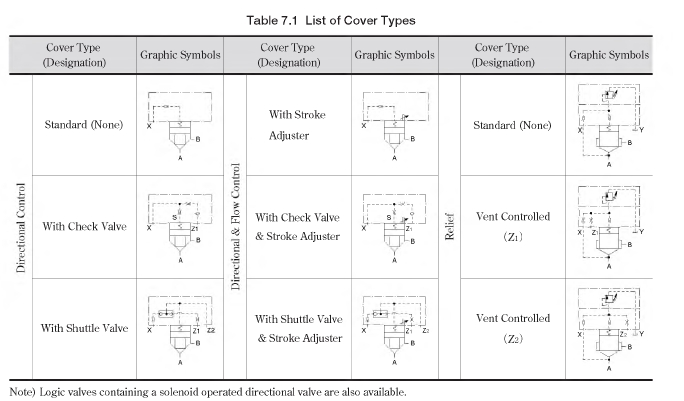

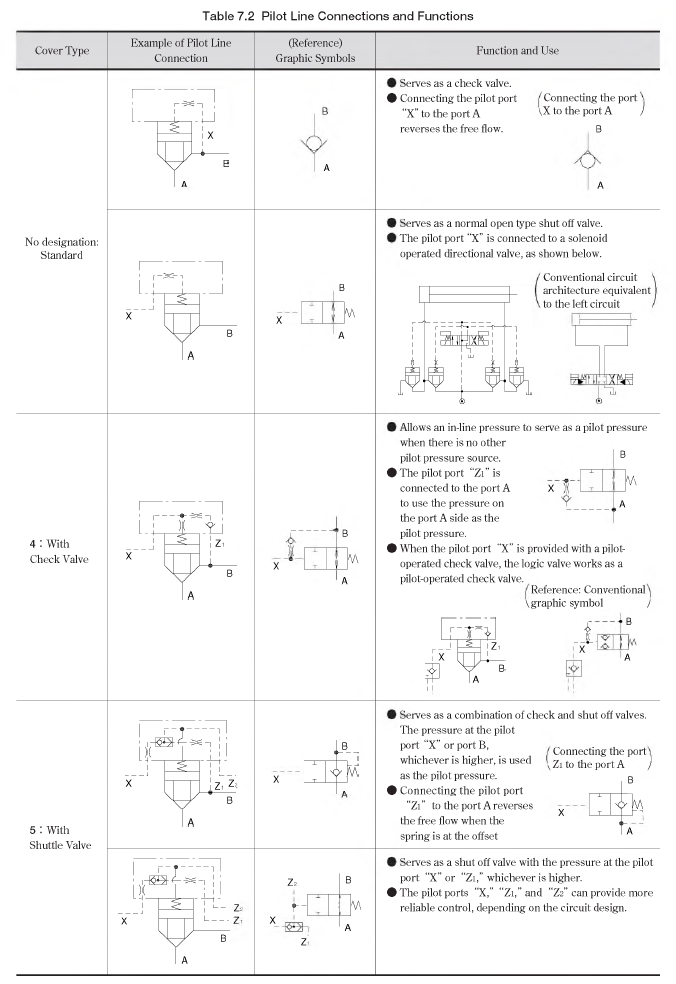

Yuken Logic Valves

These valves are comprised of cartridge type elements and covers with pilot passages. Although they are two-port valves designed to simply open/close the poppets according to pressure signals from the pilot line, various types may be combined for direction, flow rate, and pressure control. Standard covers, which have several pressure signal ports and control valves, including pilot operated relief valves, are available for control purposes.

The covers are spigot mounted so that there is no risk of external oil leakage.

Logic valves provide fast-response, high-pressure, and high-flow control. They are typically applied to machines that involve high-speed actuator operation, such as die-cast machines, injection molding machines, and press machines. In addition to the general logic valves shown in Fig. 7.1, servo-valve-integrated logic valves, consisting of a cover and a proportional valve or a servo valve, are available for highly accurate control. Such a logic valve accurately determines how much the logic valve opens, based on a deviation between the feedback signal from the displacement sensor on the main spool and the input signal to the proportional or servo valve.

The logic valves have the following features.

(1) Multifunction performance in terms of direction, flow, and pressure can be obtained by combining elements and covers.

(2) Various functions can be achieved, depending on the pilot line connection.

(3) Poppet-type elements virtually eliminate internal leakage and hydraulic locking. Because there are no overlaps, the response time is very short, permitting high-speed shifting.

(4) For high pressure, large capacity systems, optimum performance is achieved with low pressure losses.

(5) Since the logic valves are directly incorporated in cavities provided in blocks, the system faces fewer problems related to piping such as oil leakage, vibration, and noise, and higher reliability is achieved.

(6) Multi-function logic valves permit compact integrated hydraulic systems that reduce manifold dimensions and mass and achieve lower cost than that of the conventional types.

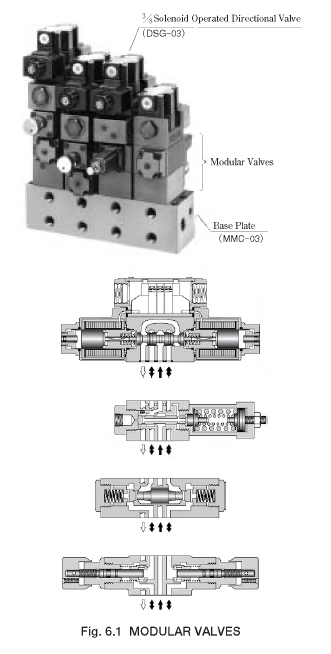

Modular Valves

These valves, including the pressure control, flow control, and directional control types, have standardized mounting surfaces that conform to the ISO standards for solenoid operated directional valves. They are stacked on a base plate and referred to as sandwich valves or stack valves. They are available in nominal sizes of less than 1/8 and 1/8 to 1 1/4. Because of easy circuit building, they are more popular than the logic valves.

These modular valves provide the following advantages.

(1) Compact stacking

These valves require very small mounting space.

(2) Easy circuit building

These valves eliminate the necessity for a large part of piping and assembly work, allowing easy and quick circuit building.

(3) Improved reliability

These valves are stacked together without piping; therefore, they are almost free from problems such as oil leakage, vibration, and noise.

(4) Easy maintenance due to integrated functions Note that the number of stacking layers is subject to the bolt strength. Also, due caution should be paid to the maximum flow and the pressure loss.

Pilot Operated Flow Control and Check Valves

These valves are pilot-operated. They control the flow with a hydraulic cylinder to accelerate or decelerate the actuator without shock.

Other flow control valves described below are available

• Flow Control and Relief Valves

These valves contain a flow control valve and a relief valve, the combination of which achieves a pump discharge pressure almost equal to the load pressure. Even when the load pressure is low, the pump discharge pressure does not increase to the control limit, ensuring power-saving operation of the system.

• Flow Dividers

These valves are used to synchronize two or more actuators. They have one inlet port and two outlet ports so that the inlet and outlet flows can be regulated to certain levels, regardless of the load.

• Priority Control Valves

These valves are incorporated in power source systems for vehicles, etc. If pump supply flow is at or below a preset level, the valves allow all of the flow to go to the priority line. If it is above the preset level, they direct the excess flow to the bypass line.

• Shut Off Valves

These valves prevent counter load from decreasing when the cylinder outlet pressure falls because of damaged piping or rubber hoses. When detecting that the cylinder is rapidly moving down, these valves quickly close to shut off the flow.

Yuken Feed Control Valve Released in 1965

Features

1. Provides seamless feeding speed control in two modes (regardless of the cutting resistance and the fluid temperature)

2. Very compact, compared to previous feed control valves.

3. Can be easily mounted/demounted with gaskets.

4. Allows direction switching to be made either with a solenoid pilot or manually.

Specifications

Max. Press.: 7 MPa (1 015 psi)

Max. Flow: 50 L/min (13.2 U.S.GPM)

Coarse Feed: 2 L/min (.528 U.S.GPM)

Fine Feed: 0.5 L/min (.132 U.S.GPM)

Weight: 22 kg (48.5 lbs.)

Feed Control Valves

These valves are a combination of a flow control and check valve and a deceleration valve; they are used mainly for feed control of machine tools. Switching from rapid traverse to feed is made by a cam operation, and the feed speed is controlled with a flow control valve. Rapid return is free of cam actuation. Two-speed mode with two flow control valves is also available.