Pressure-Relief Valves

Pressure-relief valves limit the maximum pressure in a hydraulic circuit by providing an alternate path for fluid flow when the pressure reaches a preset level. All fixed-volume pump circuits require a relief valve to protect the system from excess pressure. Fixed-volume pumps must move fluid when they turn. When a pump unloads through an open-center circuit or actuators are in motion, fluid movement is not a problem. A relief valve is essential when the actuators stall with the directional valve still in shifted position.

A relief valve is similar to a fuse in an electrical system. When circuit amperage stays below the fuse amperage, all is well. When circuit amperage tries to exceed fuse amperage, the fuse blows and disables the circuit. Both devices protect the system from excess pressure/current by keeping it below a preset level. The difference is that when an electrical fuse blows, it must be reset or replaced by maintenance personnel before the machine cycles again. This requirement alerts electrician’sabouta possible problem before restarting the machine. Without the protection of a fuse, the electrical circuit would finally overheat and start a fire.

Similarly, in a hydraulic circuit, a relief valve opens and bypasses fluid when pressure exceeds its setting. The valve then closes again when pressure falls. This means that a relief valve can bypass fluid anytime, or all the time, without intervention by maintenance. Many fixed-volume pump circuits depend on this bypassing capability during the cycle, and some even bypass fluid during idle time. A well-designed circuit never bypasses fluid unless there is a malfunction, such as a limit switch not closing or an operator over-riding the controls. This eliminates most overheating problems and saves energy.

There are two different designs of relief valves in use: direct-acting and pilot-operated. Both types have advantages and work better in certain applications.

Tandem Cylinder

A tandem cylinder, shown in Fig. 1.7, is used in applications where a large amount of force is required from a small-diameter cylinder. Pressure is applied to both pistons, resulting in increased force because of the larger area. The drawback is that these cylinders must be longer than a standard cylinder to achieve an equal speed because flow must go to both pistons.

Through-Rod Cylinders

These are similar in construction to the standard double-acting cylinders, but have a cylinder rod extending through both cylinder end caps. Although it is possible to have both the piston rods with different diameters at each end of the cylinder, generally the rods have the same diameters. The main applications of through-rod cylinders are as follows: the same speed is required in both the directions, both ends of the rod can be utilized to do work and the non-working end is used to indicate or signal the position of the load. In some applications, the rod is fixed at both the ends and the cylinder body carrying the load moves on the rod.

A major problem in the manufacture of through-rod cylinders is achieving the correct alignment and concentricity of cylinder bore, piston, end caps and rods. Any misalignment can result in excessive seal wear and premature cylinder failure.

Displacement Cylinders

A displacement-type hydraulic cylinder shown in Fig. 1.8 consists of a rod that is displaced from inside a tube by pumping hydraulic fluid into the tube. The volume of the rod leaving the tube is equal to the volume of fluid entering the tube, hence the name “displacement cylinder.”

The rod of the displacement cylinder is guided by bearings in the nose or neck of the cylinder body. A collar on the end of the rod prevents it from being ejected and limits the stroke of the cylinder. Elastomer seals in the neck prevent any leakage of fluid along the outside of the rod. This design is a single-acting “push” or extension cylinder, which has to be retracted by gravity, a spring or some external force. The bore of the cylinder body does not require machining other than that for the neck bearing and the inlet port; the manufacturing cost is, therefore, low when compared with other types or hydraulic cylinders.

The maximum thrust exerted by a displacement cylinder is given by

Double-Acting Cylinder with a Piston Rod on Both Sides

A double-acting cylinder with a piston rod on both sides (Fig.1.5)is a cylinder with a rod extending from both ends. This cylinder can be used in an application where work can be done by both ends of the cylinder, thereby making the cylinder more productive. Double-rod cylinders can withstand higher side loads because they have an extra bearing, one on each rod, to withstand the loading.

Spring-Return Single-Acting Cylinder

A spring-return single-acting cylinder is shown in Fig.1.3.In push type [Fig. 1.3(a)], the pressure is sent through the pressure port situated at the blank end of the cylinder. When the pressure is released, the spring automatically returns the cylinder to the fully retracted position. The vent port is open to atmosphere so that air can flow freely in and out of the rod end of the cylinder.

Figure 1.3(b) shows a spring-return single-acting cylinder. In this design, the cylinder retracts when the pressure port is connected to the pump flow and extends whenever the pressure port is connected to the tank. Here the pressure port is situated at the rod end of the cylinder.

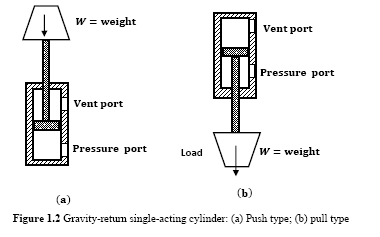

Gravity-Return Single-Acting Cylinder

Figure1.2 shows gravity-return-type single-acting cylinders. In the push type [Fig. 1.2(a)], the cylinder extends to lift a weight against the force of gravity by applying oil pressure at the blank end. The oil is passed through the blank-end port or pressure port. The rod-end port or vent port is open to atmosphere so that air can flow freely in and out of the rod end of the cylinder. To retract the cylinder, the pressure is simply removed from the piston by connecting the pressure port to the tank. This allows the weight of the load to push the fluid out of the cylinder back to the tank. In pull-type gravity-return-type single-acting cylinder, the cylinder [Fig. 1.2(b)] lifts the weight by retracting. The blank-end port is the pressure port and blind-end port is now the vent port. This cylinder automatically extends whenever the pressure port is connected to the tank.

Single-Acting Cylinders

A single-acting cylinder is simplest in design and is shown schematically in Fig.1.1. It consists of a piston inside a cylindrical housing called barrel. On one end of the piston there is a rod, which can reciprocate. At the opposite end, there is a port for the entrance and exit of oil. Single-acting cylinders produce force in one direction by hydraulic pressure acting on the piston. (Single-acting cylinders can exert a force in the extending direction only.) The return of the piston is not done hydraulically. In single-acting cylinders, retraction is done either by gravity or by a spring.

According to the type of return, single-acting cylinders are classified as follows:

– Gravity-return single-acting cylinder.

– Spring-return single-acting cylinder.

Sequencing Circuits

In many applications, it is necessary to perform operations in a definite order. Following is one of several such circuits. The components of the system are as follows. A : Reservoir and Filter ; B : Hydraulic Pump ; C : ; Relief valve : D ; F1, F2, G : Relief valve with integral check valve ; H, J : Cylinders ; I : Check Valve

The sequence of operation realized by the circuit shown in Figure 28.11-28.14 is:

Step A – Extend Cylinder H

Step B – Extend Cylinder J while holding pressure on Cylinder H

Step C – Retract Cylinder J

Step D – Retract Cylinder H

Step A

Pressing a pushbutton would start the cycle and shift the directional valve E to the position shown in Fig 28.11. At first the fluid flows through the integral check valve in G into the cap end of H and returns freely through the check valve in F2. The pump pressure is low during this period, only to the extent of pushing the load on H.

Step B

Once H reaches its rod end, the pressure builds up and now the flow develops through F1 into the cap end of J and out through the rod end to go back directly to tank through F2, E and C. Note that a pressure equal to the setting of the valve F1 is maintained on H. When J is fully extended, pressure increases further and is limited by the setting of D, providing overload protection to B.

Step C

Similarly, when the other solenoid of E is energized, the directional valve shifts to the other position, as shown in Fig. 28.13. Now, pump delivery is directed through D, E and F2, into the rod end of J. As before, the flow out of the cap end of J flows to tank through F1, E and C. Step C is illustrated in Fig. 28.13.

Step D

On completion of Step C, the pressure increases again, and the flow is directed through F2 to the rod end of H and out through the cap end to flow into the tank through the valve G at its pressure setting and then freely to tank through F1, E and C. Note that F2 maintains a pressure equal to the setting of H at the rod end of J during the retraction of H. Note further that, while H is retracting, a back pressure is provided to it by G, to prevent rapid falling of the load during lowering, under gravity.

In the above circuit, sequencing is achieved by grading the pressure settings of the relief valves. Note that sequencing can also be achieved electronically by PLC control of the solenoids of separate directional valves driving H and J.

Regenerative Reciprocating Circuit

Conventional reciprocating circuits use a four-way directional valve connected directly to a cylinder. In a regenerative reciprocating circuit, oil from the rod end of the cylinder is directed into the cap end to increase speed, without requiring to increase pump flow. Such a circuit is shown below in Figures 28.9-28.10. The circuit components are : A : Hydraulic Pump, B : Relief valve, C : Four-way two position solenoid operated valve, D : Double-acting Single-rod Cylinder. The operation of the regenerative circuit is shown in Figures 28.9-28.10.

Regenerative Advance

In Figure 28.9, the “B” port on the directional valve C, which conventionally connects to the cylinder, is plugged and the rod end of the cylinder is connected directly to the pressure line. With the valve shifted to the left most position, the “P” port is connect to the cap end of the cylinder. If the ratio of cap end area to rod end annular area in the cylinder is 2:1, the pressure being the same at both end, the force at the cap end is double that at the rod end. There is therefore a net force on the cylinder to move the load. Similarly, at any speed of the cylinder, the flow into the cap end would be double that of the rod end. However, in this connection, the flow out of the rod end joins pump delivery to increase the cylinder speed. Thus only half of the flow into the cap end is actually supplied by the pump. However, the pressure during advance will be double the pressure required for a conventional arrangement for the same force requirement. This is because the same pressure in the rod end, effective over half the cap end area, opposes the cylinder’s advance.

In the reverse condition shown in Figure 28.10, flow from the pump directly enters the rod end of the cylinder through two parallel paths, one through the directional valve and the other directly. Exhaust flow from the cap end returns to the tank conventionally through the directional valve. Note that, in contrast to the conventional case, the force on the cylinder as well as the pump flow remains unchanged during extension and retraction. Thus, the speed of the piston during both advancement and retraction remain same.

Reciprocating Cylinder with Automatic Venting at End of Cycle

A reciprocating cylinder drive is a very common hydraulic system. In systems where it is not necessary to hold pressure at the end of a cycle, it is desirable to unload the pump by automatically venting the relief valve, to save energy. Figures 28.5-28.8 show such a system. The system components are : A : Reservoir with Filter, B : Hydraulic pump, C, E : Check valve, D : Pilot operated relief valve, F : Two-position electro-hydraulic pilot operated Four-way Directional valve, G : Cam operated pilot valve, H : Double acting Single rod Cylinder, I : Limit Switch.

Extension Stroke

Consider the beginning of the machine cycle when the solenoid of the spring offset directional valve F is energized. Pump output is connected to the cap end of the cylinder. The vent line drawn from the directional valve output connected to the cap end of the cylinder is blocked at the cam-operated pilot valve G. Thus, vent port of the relief valve D is blocked, and the cylinder moves under full pump pressure applied to the cap end.

Retraction Stroke

At the extreme end of the extension stroke, the limit switch is made on by the cylinder rod to break the solenoid circuit for the directional valve F. The directional valve now shifts to its right position and the pump gets connected to the rod end of the cylinder which now retracts. Note that the relief valve vent connection is still blocked.

Automatic Venting at End of Retraction Stroke

At the extreme end of the retraction stroke, the cam on the cylinder is operated by the rod to shift valve G. The relief valve vent port is thus connected, through E and G, to the line from the cap end of the cylinder, and to tank through the F and the inline check valve C. This vents the relief valve D and unloads the pump.

Push Button Start of Cycle

If another cycle of reciprocating motion is desired, a start button connected to the solenoid circuit is depressed to energize the solenoid, and, in turn, the directional valve shifts to direct pump output into the cap end of the cylinder. This causes the check valve in the vent line to close. Pressure again builds up and the cylinder starts extending. This releases the cam, which, under spring action, shifts and the vent port of E is again blocked at G. Thus the cycle repeats.

Selection of System Operating Pressure

The circuit shown in Figures 28.2-28.4 allow selection of operating pressure limits in a hydraulic system from three options, namely, two maximum pressures, plus venting. First note the components, namely, A: Reservoir with Filter, B: Hydraulic Pump, C, E: Pilot Relief Valve, D: Solenoid activated Four-way Directional valve.

Venting Mode

In Figure 28.2, both solenoids a and b of the directional valve D are de-energized. The open-center spool is centered by the valve springs, and the vent port on the relief valve is opened to tank. Therefore, the pump flow opens to tank at a very low pressure.

Intermediate Maximum Operating Pressure

In Figure 28.3, the left-hand solenoid a of the directional valve is energized. The valve spool is shifted to the leftmost position and connects the relief valve vent port to the remote control valve. Pump flow is now diverted to tank when the pressure setting of the remote valve E is reached.

High Maximum Pressure

In Figure 28.4, the right solenoid b of the directional valve is energized. The spool now shifts right to connect the relief valve vent port to a plugged port in the directional valve. The relief valve C now functions at the setting of its integral pilot stage.