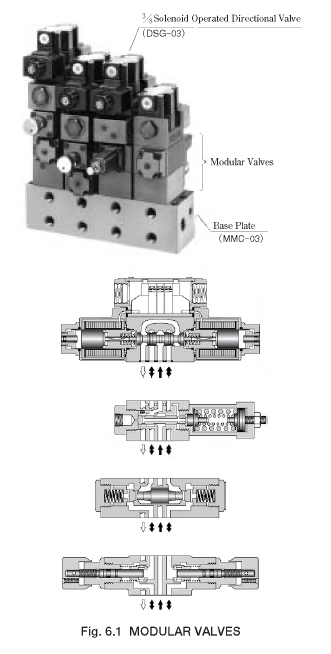

These valves, including the pressure control, flow control, and directional control types, have standardized mounting surfaces that conform to the ISO standards for solenoid operated directional valves. They are stacked on a base plate and referred to as sandwich valves or stack valves. They are available in nominal sizes of less than 1/8 and 1/8 to 1 1/4. Because of easy circuit building, they are more popular than the logic valves.

These modular valves provide the following advantages.

(1) Compact stacking

These valves require very small mounting space.

(2) Easy circuit building

These valves eliminate the necessity for a large part of piping and assembly work, allowing easy and quick circuit building.

(3) Improved reliability

These valves are stacked together without piping; therefore, they are almost free from problems such as oil leakage, vibration, and noise.

(4) Easy maintenance due to integrated functions Note that the number of stacking layers is subject to the bolt strength. Also, due caution should be paid to the maximum flow and the pressure loss.