Direct Drive Servo Valves

The valves directly drive a spool with a small and high-power linear motor. Direct drive servo valves electrically send the spool position data to the controller to provide quick response and high contamination resistance. These valves are available in two types: direct spool control and pilot operation (a combination of small valves).

Figure 9.7 shows illustrations of direct drive servo valves. Table 9.2 and Figures 9.8 and 9.9 give the specifications, flow rate characteristics, and frequency response of typical direct drive servo valves.

Electro-Hydraulic Two-Stage Servo Valves

Nearly all types of servo valves are based on common principles. Electro-hydraulic two-stage servo valves generally operate with force feedback. Given that valve pressure drop is constant, the valves control the output flow in proportion to the input signal. Therefore, they can be used to drive a hydraulic cylinder or motor at a speed proportional to the input current.

Figure 9.5 provides illustrations of an electro-hydraulic servo valve. The valve contains identical torque motors in parallel, which serve as a nozzle flapper amplifier with movable coils and nozzles. Coil displacement always determines the spool position. To ensure reliable pilot operation, the valve is provided with a filter prior to the pilot line, as well as a high-performance line filter prior to the valve inlet. Table 9.1 shows valve specifications, and Fig. 9.6 provides frequency response variations.

Servomechanism (Tracking Mechanism)

A servomechanism is an automatic control system designed to operate in accordance with input control parameters. The mechanism continuously compares the input signal to the feedback signal to adjust the operating conditions for error correction. Commercially available servo systems vary according to their methods for error detection, amplification, communication, and output.

Hydraulic servo systems have been widely applied in general industrial areas, as well as in the airline, maritime, and military industries. Servo systems, capable of automatic position, speed, and force (load) control with high accuracy and quick response, are used for high-speed injection molding, die-casting, rolling mill, press machines, industrial robots, simulators, testing machinery, and table feeders.

A hydraulic servo system consists of an actuator (hydraulic motor/cylinder), servo valves, sensors, and a servo amplifier, as shown in Fig. 9.1. Figure 9.2 shows a servo system applied to a high-speed vibration test machine.

There are two types of electro-hydraulic servo valves: the pilot operated type, which drives a torque motor to amplify the hydraulic power with a nozzle flapper mechanism, and the direct type, which directly drives a spool with a linear motor and electrically provides feedbacks about the spool position. Mechanical servo valves are also available that have a stylus at one side of the spool to control the flow direction by the mechanical motion of the stylus.

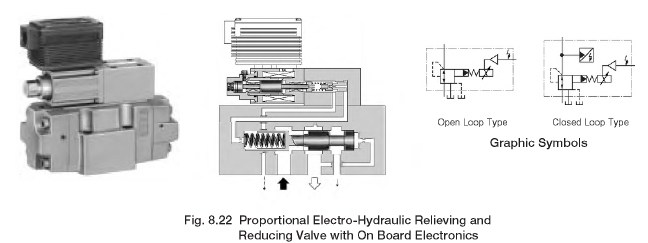

Yuken Proportional Electro-Hydraulic Relieving and Reducing Valves with On Board Electronics

These valves are a combination of a proportional electro hydraulic pilot relief valve and a pressure reducing and

relieving valve. They can control hydraulic system pressures proportionally to the controlled input voltage. As the valves have a relieving mechanism, a good response speed in reducing the pressure, even at a large load capacity, can be obtained.

Yuken Proportional Electro-Hydraulic Directional and Flow Control Valves with On Board Electronics

These valves are a combination of a directional and flow control valve and a power amplifier. The flow rate can be

controlled by changing an input voltage to the solenoids, and the direction of the flow can be controlled by providing the current to either of the two solenoids. This type of valve is highly popular abroad because of its ease of use.

Yuken Proportional Electro-Hydraulic Relief Valves with On Board Electronics

These valves consist of a proportional electro-hydraulic relief valve, a power amplifier, and a pressure sensor. They can control hydraulic system pressures proportionally to the controlled input voltage.

Hybrid Proportional Electro-Hydraulic Control Valves

These valves contain a combination of an amplifier-integrated proportional valve, pressure sensor, and displacement sensor in order to improve the functionality and ease of use. They have a closed minor feedback loop that greatly improves pressure control linearity, hysteresis, and stability. The valves offer the following features.

(1) With a hydraulic power source, DC 24 V power supply, and command signal voltage (0 to 5 V), the valves allow easy building of proportional control systems and do not require any separate amplifier or electric controller.

(2) They accommodate sensors that permit system pressures to be monitored on a remote digital indicator.

(3) The valves feature monitoring of sensor output signals and deviation signals from a closed loop; systems can be built that detect failures of hydraulic components or conduct predictive prognostics.

Circuit Examples of Proportional Electro-hydraulic Control Valves

Figures 8.14 and 8.15 compare circuits equipped with the general hydraulic control valves and the proportional electro-hydraulic control valves. As is evident from the figures, the proportional electro-hydraulic control valves can generally replace many of control valves in hydraulic systems. Also, they simplify the circuit and the system sequence, bringing about easier maintenance and management. Furthermore, the proportional electro-hydraulic control valves provide continuous control, which is impossible with any combination of the general hydraulic control valves. With the proportional electro-hydraulic control valves, hydraulic systems may be used in a significantly wider range of application areas.

Power Amplifiers For Proportional Electro-Hydraulic Control Valves

Amplifiers serve as a drive for the proportional electro-hydraulic control valves. They convert signal voltage from a setting adjuster to a current. Then, they amplify and feed the current to the solenoid to operate the valves for pressure and flow control. The available types of the amplifiers are: DC input, DC input feedback, slow up-down, DC input with minor feedback, and shock-less.

Proportional Electro-Hydraulic Directional and Flow Control Valves

These valves accommodate flow and direction control functions for an actuator. The flow rate can be controlled by changing an input current to the solenoids and the direction of the flow can be controlled by providing the current to either of the two solenoids. These valves have linear variable differential transformers for detection of the spool position so that they can provide quick-response and high-accuracy control.

Some of the valves can adjust the spool shift timing for operation without shock.